BLOG

The making process of handmade mulberry silk duvet.

There are six steps of the making process of our handmade mulberry silk duvet:

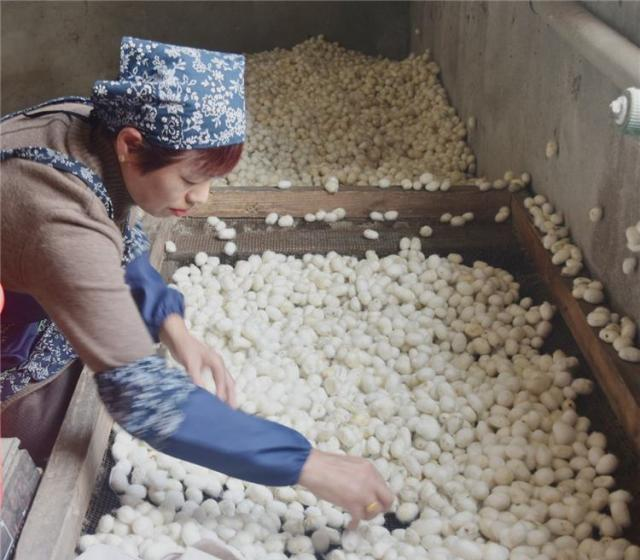

Step 1 Cocoon selection:

Good silks are double Palace cocoons. There are really two silkworm babies after peeling. The two silks spin silk intertwined. The cocoon formed in this way is warmer and tighter than the single Palace cocoon.

Step 2 Cocoon Cooking:

Cook the selected cocoon over a slow fire for two hours, and properly moisten and dissolve the sericin around the cocoon silk by using the action of water and heat, so as to weaken the glue force between cocoons and silk, which is conducive to silk reeling. After two hours of cooking, remove the cocoon from the pot, wash the boiled sericin and impurities, and cool them to prepare for the next cocoon stripping.

Step 3 Cocoon stripping:

Peel the boiled cocoons in warm water, remove the pupae, slowly open the cocoons one by one, put the peeled cocoons on your hands, and make them into small cotton bags. 5 ~ 6 sets are a small cotton bag.

Step 4 Kaijin:

Then open each small cotton bag one by one, that is, open the small cotton bag into a big silkworm hat with bamboo support, and open five small cotton bags into a big silkworm hat. The opened cotton bag looks like a hat.

Step 5 Drying:

After finishing and drying the opened silkworm hat, you can see its white as jade, flawless silk tire with clear silk path and silver light. Then put dozens of silkworm hats together and cut them into square cotton pieces. The cut silkworm hats can be used as duvets.

Step 6 Drawing:

Four people are used to pulling the “hat” slowly into the size of the whole quilt, and four people work at the same time to lay and stack the good word layer by layer. All of them adopt the new process of “full-width plane mesh stacking”, which is fixed vertically and horizontally by the core path layer by layer, so as to achieve the process effect of no turnover for 20 years. This process is directly related to the process and quality of the whole quilt, and the uniformity and service life will be more prominent. It was pulled by two people a few years ago. A quilt should fit together piece by piece. The disadvantage is that it is easy to be displaced by the tire.

Step 7 Assembly of silk quilt:

Put the quilt cover on the console and put the silk quilt tire on the quilt cover. Start sewing from one side of the silk quilt, sew the quilt tire and quilt cover together, sew a circle, and the quilt tire and quilt cover are fixed together. Then, roll up the quilt from both sides of the head and tail to the full lock position, turn the quilt outward from the middle of the two layers of fabrics at the pull lock, so that the silk quilt tire can be turned into the quilt cover. After turning over, find 9 points evenly on the quilt and fix them with needle and thread at each point, so as to prevent the quilt from moving. Shake the quilt flat and tidy up the four quilt corners. Finally, fold the mulberry silk duvet, put it into the plastic packaging bag, fasten the bag mouth, and put it into the packaging box.